Heat Press SleeveLock Single Station Platen

- SKU:

- HPSLSS

- Weight:

- 45.00 LBS

- Shipping:

- Calculated at Checkout

Heat Press SleeveLock Single Station Platen

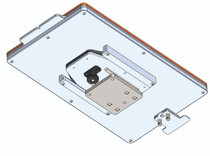

The SleeveLock Printing System transforms any single-station heat press into a high-throughput, precision sleeve-printing workstation. Built around a dual-pallet, front-to-back sliding platform, the system lets operators load and prep one sleeve while the other is being pressed—eliminating idle time and dramatically increasing hourly output without adding another press.

At the heart of the system is our innovative floating platen and locking architecture. The rear cuff lock captures the sleeve first, anchoring the garment in perfect alignment. Once the cuff is secured, the operator slides the sleeve forward and engages the front shoulder lock, stretching and positioning the sleeve flat and square across the pressing surface. This two-stage locking method removes wrinkles, eliminates skew, and ensures that every print lands exactly where it should, even on stretchy performance fabrics.

The floating platen design allows the garment to self-align as it is locked, preventing fabric bunching and maintaining even pressure across the print area. This is especially critical for sleeve graphics, where small shifts or distortions are immediately visible. The rigid aluminum core and precision-machined locking components provide repeatable accuracy, press after press.

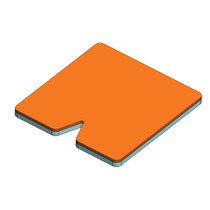

Designed specifically for single-station heat presses such as Stahls/Hotronix models equipped with our Quick Release system, the SleeveLock System mounts in seconds and locks solidly into place. The long, narrow sleeve pallets are padded with high-temperature, resilient silicone to provide uniform pressure and excellent heat transfer while protecting delicate garments.

How it Works in Production:

- While one sleeve is under the heat platen being pressed, the second pallet is in the open load position.

- The operator loads the next sleeve, locks the cuff behind the platen, slides it forward, and locks the shoulder at the front.

- As soon as the press cycle finishes, the finished sleeve is removed and the pre-loaded pallet is slid into the pressing position—no waiting, no re-alignment, no wasted motion.

The result is a true leap in productivity for decorators doing sleeve logos, sponsor prints, or multi-location garment decoration. What once required awkward garment handling and slow, one-at-a-time pressing becomes a smooth, repeatable, production-grade process. Built in the USA from precision-machined aluminum and industrial grade components, our SleeveLock Single Station Platen System is designed for professional shops that demand speed, consistency, and long-term durability. It is the fastest and most accurate way to add high-margin sleeve printing to any single-station heat press workflow.

We offer a guarantee of satisfaction on all of our products. For returns, please contact: inquiries@actionengineering.com

Shipping

We ship products through UPS Ground and Freight. Please contact us for more information.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are dimension and weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.