The Real Reason You Should Be Using Rubber on Pallets

Posted by Erik Naftal, Gerrai Ramirez on Feb 13th 2019

Here's The Facts:

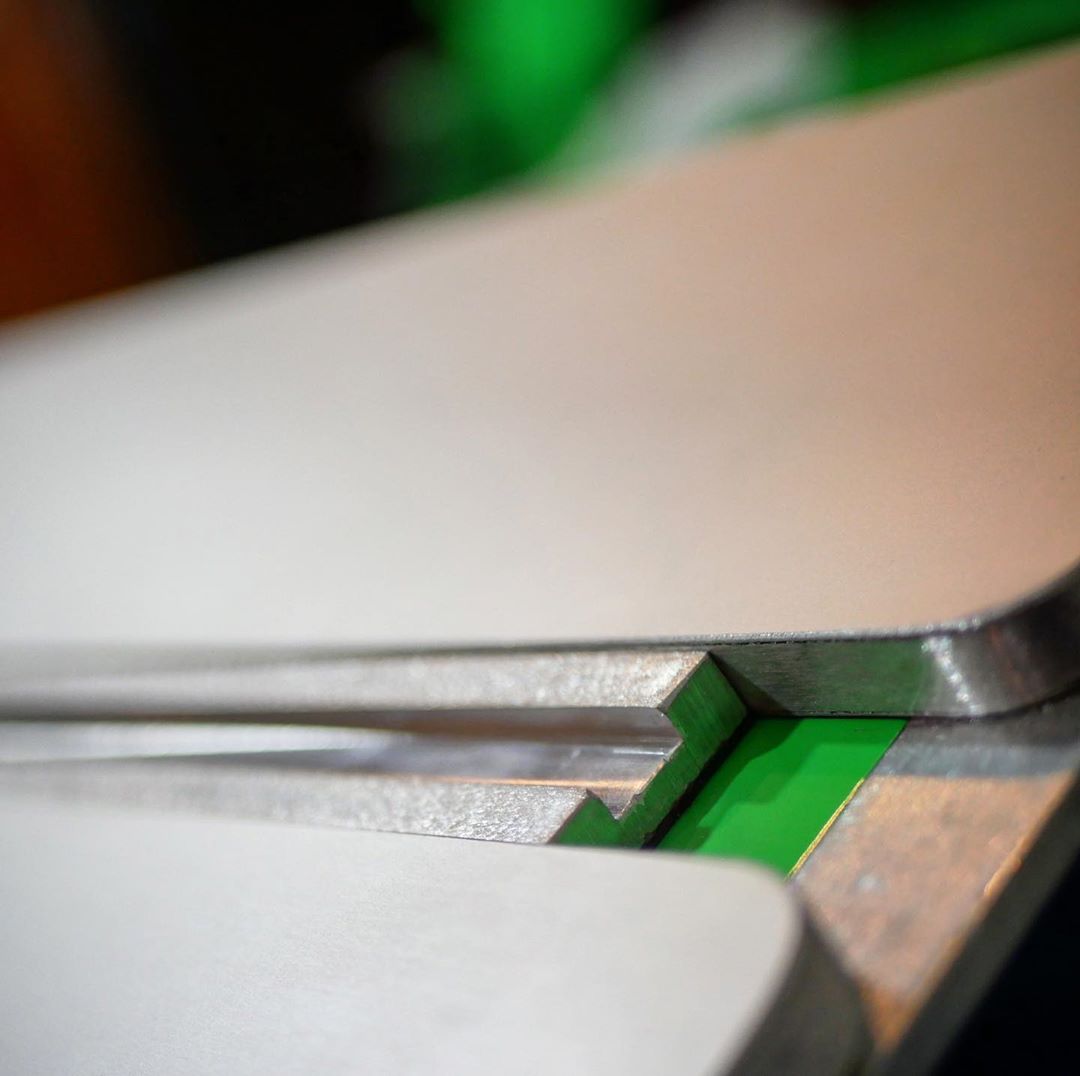

Soft Top Rubber has been used in Textile Printing on pallets for at least 4 decades. During that time, the material was refined to improve all of the characteristics that are important to screen printing. Our Rubber has a smooth, flat surface that is blemish-free with no gashes, bubbles, or aberrations of any kind that will not transfer as a background or ghost image to your final print.

Higher Print Quality

The 1/8” thick, heat resistant material of rubber provides

an excellent printing surface across the board. Slight inaccuracies in the

alignment of your printing plane are absorbed by the rubber while providing an improved

ink shear & penetration. Other benefits noted by screen printers is that it

reduces pinholes, increases mesh life, and gives you better ink penetration on

garments. The material is also designed to withstand very high flash

temperatures and increase the heat retention of your pallet. Your pallet will

stay warm for a longer period of time than a pallet without. Pallets that stay

warm also require less flash time. However, if left under a flash cure unit,

the rubber starts to smoke and then melt and burn. This is a downside since the

burned rubber will need to be stripped and removed which costs time and money.

- More Adherence in Print to Garment

The compression of the rubber allows the garment weave to flex and stretch when the squeegee presses hard into the rubber. This stretch behavior allows for better penetration of the ink into each weave. An ideal print is ultra-smooth and can withstand being washed a million times. The more ink that penetrates into the material the better. Your final print will have a higher quality “hand feel” and supreme durability.

- Reduced Costs, Flashing Times, & Increased Production

This is the most important benefit. Solid Aluminum is the

world’s best material for printing. It is cost efficient, flat, durable, heat

resistant, and rigid. Also important is that it disperses heat very quickly.

This is sometimes good but not when flashing. When you add rubber to aluminum

pallets it dramatically increases the heat dissipation time while “blanketing”

the aluminum to trap heat in. Heat costs money and time to generate so if you

keep pallets warm they will require less heat between flashes. This means not

only are you saving money on the cost of running your flash cure unit, but you

are also increasing production.

- Easy Control of Consistency

There is a noticeable difference in the consistency over both

long & short runs. The rubber acts to reduce mesh damage over time and

emulsion breakdown. It will also require less overall screen attention during

the run, leaving free time to manage other production activities.

Removing Rubber from the Surface

One of the challenges Screen Printers face is the process of replacing their rubber. Accidents happen -- business kicks up and suddenly one of the pallets are burned, leaving you no option but to stop that press and replace the rubber topping. No matter what kind of rubber you get, it does not last forever. There are several ways to do this, but we have found that heating under the flash to loosen the adhesive bond helps to get it off, as the rubber is heavily secured by settled adhesive.

Click here to get our Rubber Removal Guide

Replacing Your Soft Top Rubber

Once your aluminum pallet is cleaned and ready to go, you're ready to replace the rubber. There are two methods of doing this. The traditional method, and our Peel & Stick Rubber method. The same rubber is used in both methods with the ultimate goal of your aluminum pallet being evenly topped with a new sheet of rubber.

Peel & Stick Method: